It may result in additional engineering time needed reduced reliability or perhaps increased image processing times to achieve a working system.

Lighting techniques in machine vision ppt.

Machine vision capabilities br checks for br gauging or measurement.

In machine vision applications we need to provide light in a controlled way that accentuates features we care about while minimizing distracting features light from the environment is a dan ger because it may change when we don t expect it.

A machine vision system built around the right camera resolution and optics can easily.

A substandard lighting arrangement will prevent the system from working to its optimum potential.

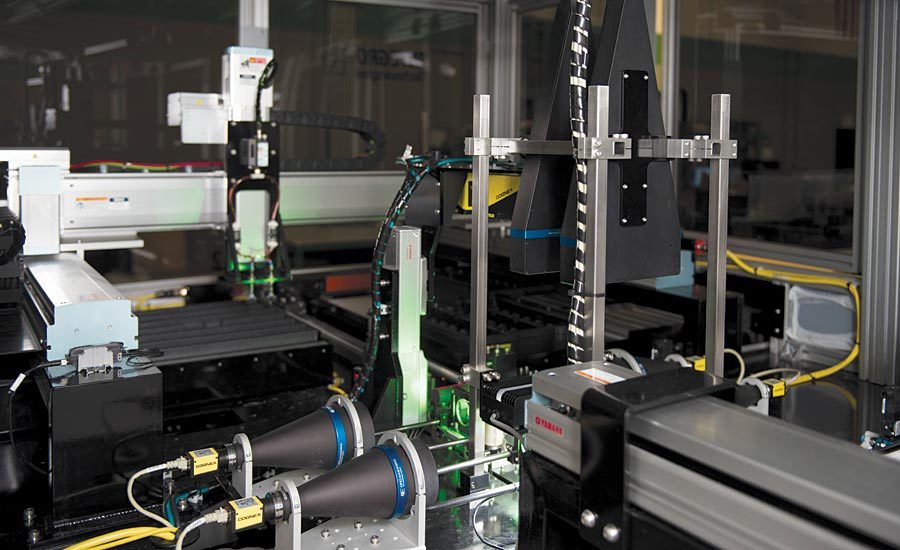

Camera and lighting technology obtaining a digital representation of an image software computational techniques to process or modify the image data analysis decisions using the results of the processing in robot control.

A variety of parameters can determine the light source which creates an interaction with the test object and its individual material properties.

The three areas you must focus on to ensure image stability are.

Scene machine vision excels at quantitative measurement of a structured scene because of its speed accuracy and repeatability.

Lighting techniques for machine vision.

Correct lighting is critical to a successful machine vision installation.

Machine vision as a sensor for robots.

Finding the right light source can take a seemingly difficult application and simplify it.

3 machine vision in automation.

For example on a production line a machine vision system can inspect hundreds or even thousands of parts per minute.

2 comparison and contrast of common vision lighting sources.

Dimensions br serial numbers br presence of components br pattern matching br blob analysis or edge detection br optical character recognition ocr br and barcode decoding br surface inspection br colour analysis br.

Criteria as applied to machine vision.

The key to deploying a robust machine vision application in a factory automation setting is ensuring that you create the necessary environment for a stable image.

Pete kepf cvp www kepf me motion robot guidance defect flaw detection inspection grading sorting identification verification data acquisition.

For example whereas led lighting has a longer life expectancy quartz halogen lighting may be the choice for a particular inspection because it offers greater intensity.

The main task of lighting is to create contrast between the object features to be detected.

How light is reflected and may pose challenges in creating a good image.

Vision lighting and imaging optics are best designed together as a system.

Lighting lensing and material handling.

How to choose the right lighting for machine vision applications lighting can also affect how easy it is for computer analysis to produce a workable image.